Relying on the self-organization approach of eutectics solidified from the melt, this is an original research line, with good scientific production and international leadership.

Research

-

PROCACEF > Research

Our research lines

At the PROCACEF group we perform research on MICROSTRUCTURED COMPOSITES for energy, the environment or photonics; on materials and devices for HYDROGEN technologies and for ENERGY STORAGE, and in LASER PROCESSING.

RESEARCH LINES

MICROSTRUCTURED COMPOSITES FOR ENERGY, ENVIRONMENT OR PHOTONICS

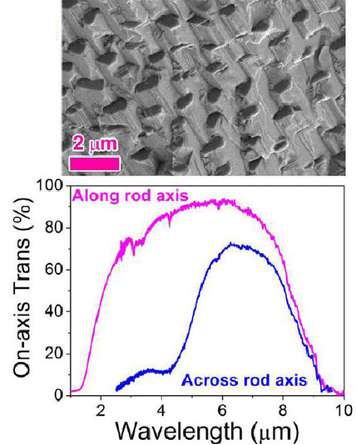

Solidified eutectics consists of two or more phases organized in rather homogeneous arrangements of different types, with micron or submicron size phases and clean and strongly bonded interphases. Their most relevant properties stem from the synergy of appropriate phase properties with these microstructural features. The procedure for their manufacture is critical to the final properties, and involves solidification from the melt. We possess expertise and appropriate equipment for Bridgman solidification (fluorides) and laser melting (laser floating zone and surface melting).

Our present interest focus on ion-conductive ceramics with aligned pores suitable as supporting oxide in dual membranes of molten carbonates (PROJECT EUMEM, T02-20R DGA), and in the investigation of eutectics of ionic and mixed conductive oxides for oxygen storage or electrodes in solid oxide electrochemical devices (PROJECT NAME/3DPASSION; PROJECT FLASCERAMAT (finished)). )). Of particular interest is the capability of tailoring the conductivity at the interfaces of directionally solidified eutectics.

Microstructured Composites

Selected Publications

Original research line, with good scientific production and international leadership. These are our main publications.

2021

L. Grima et al., High CO2 permeability in supported molten-salt membranes with highly dense and aligned pores produced by directional solidification;

Journal of Membrane Science 630 (2021) 119057

B.M. Moshtaghioun et al., Can Y2O3-MgO eutectics be new promising structural and optical ceramics?

Acta Mater. 216 (2021) 117139

Orera, A. et al., Interfacial stability and ionic conductivity enhanced by dopant segregation in eutectic ceramics: The role of Gd segregation in doped CeO2/CoO and CeO2/NiO interfaces.

Journal of Materials Chemistry A 8 (2020) 2591

2020

RESEARCH LINES

HYDROGEN

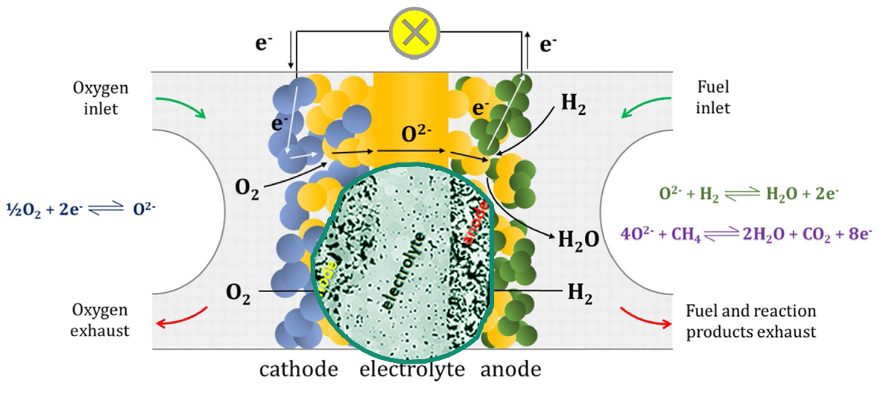

Reversible electrochemical solid oxide cells for hydrogen synthesis and its use as a fuel (SOFC and SOEC).

We are leading national and international projects on hydrogen production (SOEC), novel 3D innovative SOC designs and portable microtubular SOFC devices.

Reversible electrochemical devices electolyzer / fuel cell contribute to face the energy transition based in renewable energies and hydrogen. Electrolysis cells fed with renewables can be used to generate hydrogen when intermittent renewables are available, while this hydrogen is later converted to electricity when needed. Specifically, high and intermediate temperature solid oxide cells are very well suited as they afford higher overall efficiency. Very much is known about appropriate materials for the devices, while the main bottlenecks to deploy the technology resides in the manufacturing costs and degradation issues. Therefore, research to alleviate them is needed, as for example in materials for electrodes affording lower overpotentials at intermediate temperatures or optimum microstructural design.

We have been researching materials for solid oxide fuel cells and device manufacture since around 20 years with increasing dedication and diversification over time. Our previous knowledge of the physics of defects in oxides through spectroscopy (optical spectroscopy, raman, electron paramagnetic resonance, impedance spectroscopy), lead us to the investigation of some of these materials in microtubular solid oxide fuel cells. This opened a new avenue to investigate performance in the device of a wider range of materials, as well as the need to advance in its manufacturing at laboratory scale. We are now investigating novel manufacturing processes such as laser patterning, new cathode materials or experimental tools to investigate the oxygen activity profiles inside the devices.

Our present activities pursue developing a new generation of highly performing advanced solid state energy conversion and storage devices by the optimization of their shapes and microstructures on the basis of novel materials (NAME/3DPASSION, G-FORCE, COOPA20437). At the same time, we work in the technologies to develop solid oxide electrolyzers up to a 2kW stack (PROJECT SOEC-PPCC), and small devices based on microtubular SOFCs for portable applications (MARBLE).

HYDROGEN

Selected Publications

We are leading national and international projects on hydrogen production (SOEC), novel 3D innovative SOC designs and portable microtubular SOFC devices.

2022

A. Orera et al., Advanced metal oxide infiltrated electrodes for boosting the performance of solid oxide cells.

J. Mat. Chem. A 10 (2022) 2541

2018

RESEARCH LINES

ENERGY STORAGE

Advanced Li-ion and lead batteries.

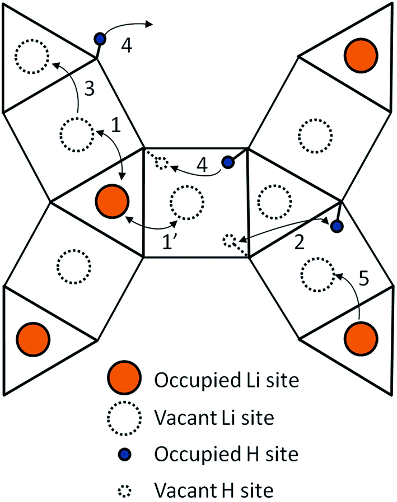

Development of electrolyte materials for All Solid State Li Batteries, and research and optimization of neutron scattering based techniques for in-operando investigation of charge-discharge processes.

Concomitant with the deployment of renewable electrical energy (solar, wind), there is an increasing need of energy storage media. All-solid-state lithium ion batteries are today considered the next major advance in batteries because of their improved properties: i) increased safety thanks to the replacement of current flammable liquid electrolytes by solid materials; ii) significant decrease of volume and weight; iii) higher stored energy owing to the use of electrolytes with larger electrochemical stability window; and iv) simpler battery design.

Our interest in the structure and transport properties of Li-ion inorganic electrolytes dates from the late 1990s, and now focusses on laser patterning of nasicon and garnet-like materials. The structural and dynamic properties of Li-conducting garnets were the object of the PhD work of our former student G. Larraz (2016). Previous work on Li-ion conductors was devoted to Li-La-Ti-O perovskites, LiMPO4 layered compounds and NASICON-like LiM2(PO4)3, among others. Presently we focus on the development of advanced ceramics for high-performance All Solid State Li metal Batteries (ASSB) (NAME/3DPASSION), and in the investigation in-operando of advanced lead batteries (NeutronBat).

Our first aim with ASSLIB is to develop novel multiscale 3D processing techniques for ASSB involving laser milling of the solid electrolytes Li7-xLa3Zr2-xTaxO12 (LLZTO) and nasicon-like Li1+xAlxGe2-x(PO4)3 (LAGP). The goal is to increase the performance at the electrolyte/electrode interfaces. Equally relevant in the development of future ASSLiB are hybrid Li-ion conductors. They would combine thermal and morphological stability of ceramic Li-conducting electrolytes with ease of handling of polymers.

The already mature lead batteries can support the immediate storage needs, contributing to a fast energy transition. We have lately performed materials research jointly with industries in the sector, contributing to this optimization. Farther reaching results are expected involving neutron scattering techniques for in-situ evaluation of these electrochemical cells.

ENERGY STORAGE

Selected Publications

Advanced Li-ion and lead batteries.

These are our main publications.

2020

2018

RESEARCH LINES

LASER PROCESSING OF MATERIALS

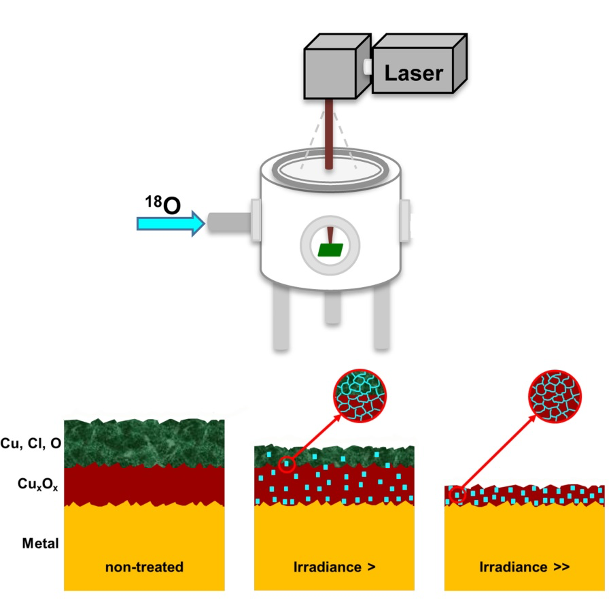

We use the laser as a tool for materials processing. We research on the laser-materials interaction, selective laser melting and surface functionalization and modification, as well as give support to industries.

The laser as a tool for materials processing joints fast processing with customization capabilities and has multiple applications in industry. Large power range, automatic control and beam shaping by optical beams allows many different processes: selective consolidation of solid loaded polymers in additive manufacturing, micro and nano-structuring using interfering lasers, selective laser melting or sintering of metals and ceramics, or surface structuring by ablating material, etc. At research level, laser – matter interaction is harnessed to achieve unprecedented properties and microstructures or to discover novel or more convenient (faster, less energy consuming, etc.) fabrication procedures.

PROCACEF research projects where laser technology is at the core are NAME/3DPASSION and EUMEM. Laser machining and structuring contributes to faster electrode processes in SOFC and SOEC cells and solid state batteries. Selective laser melting is researched as a means to obtain a micron-scale alignment of phases by scalable procedures.

Through collaboration with Sabrina Grassini from Politecnico di Torino, we also investigate laser cleaning procedures for the conservation of cultural heritage, which is applied to the elimination of corrosion present in ancient archaeological metals. A novel procedure was developed involving 18O isotopes evaluated by Time of Flight – Secondary Ion Mass Spectrometry (ToF-SIMS) to assess the driving mechanisms of laser-surface interactions. The research of laser assisted nanoparticle synthesis for application as contrast agents in imaging diagnosis is done in collaboration with Oscar Bomati-Miguel at the Universidad de Cádiz.

Added to that, a number of other collaborations and industrial projects dealing with laser surface structuring, machining or laser cleaning take benefit of our expertise and interest.

LASER PROCESSING OF MATERIALS

Selected Publications

With excellent contracts with industries.

These are our main publications.

2021

Elisabetta Di Francia et al.¸Novel procedure for studying laser-surface material interactions during scanning laser ablation cleaning processes on Cu-based alloys.

Applied Surface Science 544 (2021) 148820

Usman T. Syed, et al. Microengineered Membranes for Sustainable Production of Hydrophobic Deep Eutectic Solvent-Based Nanoemulsions by Membrane Emulsification for Enhanced Antimicrobial Activity.

ACS Sustainable Chem. Eng. 8 (2020) 16526

Cebollero et al. Optimizaton of laser-patterned YSZ-LSM composite cathode-electrolyte interfaces for solid oxide fuel cells.

J. Europ. Ceram. Soc. 39 (2019) 3466