Facilities and Singular Equipment

-

PROCACEF > Facilities and Singular Equipment

Laser Processing Labs

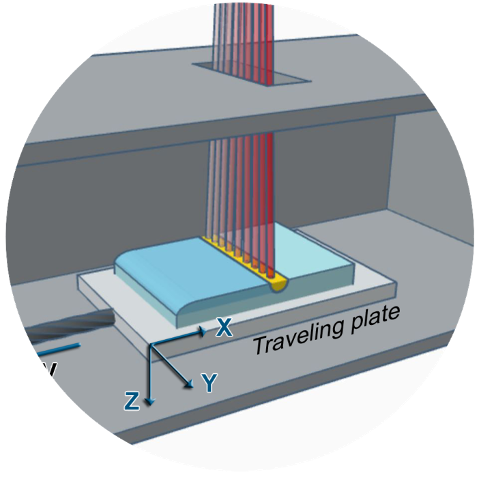

Different lasers and adjacent equipment is used for materials processing: solidification from the melt of oxide ceramics and composites, selective surface melting, laser engraving, laser structuring, laser marking, laser cleaning, etc.

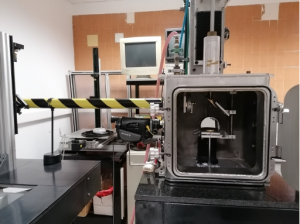

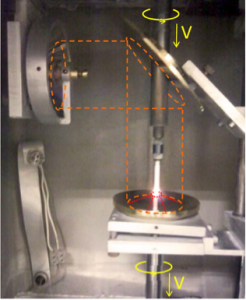

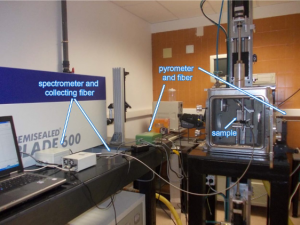

Laser Floating Zone set up: Growth Chamber equipped with an Electronic Engineering Blade 600 CO2 laser for sample heating.

Laser Floating Zone set up: Detail of the Growth Chamber

Surface laser melting / marking equipment: CO2 Slab laser (Easy mark 250). System equipped with dedicated furnace for sample preheating.

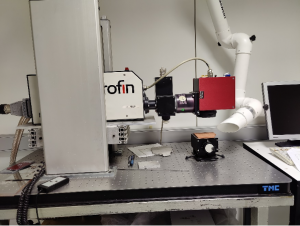

Diode-pumped Nd:YAG laser system (Rofin Sinar E-Line 20)

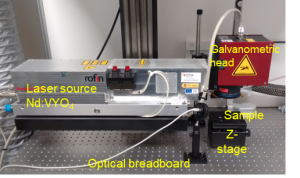

Nd:YVO4 Q-switched diode-pumped laser, Rofin PowerLine S3 SHG (532nm). The laser supports a power repetition rate from 15 to 400 kHz, with minimum pulse width of 5ns, and nominal power 2W. Its beam type is TEM00 and the quality factor M2 < 1.2.

Ceramic Processing Facilities

We have expertise and labs equipped for ceramic processing: powder mixing and milling, optimization of slurries (rheometer), ceramic shaping (slip and screen printer, 3-rol miller, slip and tape caster), sintering and thermal treatments (muffles and furnaces up to around °1500 ), or dilatometer up to 1500 °C.

Rotational rheometer Mars II (Haake, Karlsruhe, Germany) and detail. It is equipped with double cone-and-plate test geometry (double cone of 1º, = 60 mm) or disposable Al test-plates.

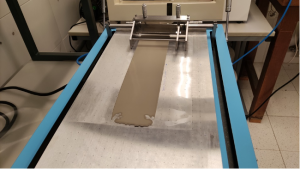

Tape caster. MSK-AFA – II Automatic Thin Film Coater from MTI Corporation.

Mufle furnaces up to 1500 °C and tubular furnaces (controlled atmosphere) up to 1500 °C

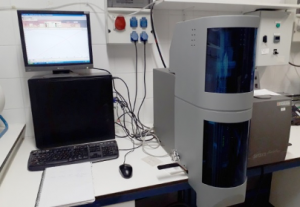

Dilatometer SETSYS from Setaram, used for determination of sintering curves and dilatometry studies up to 1500 °C

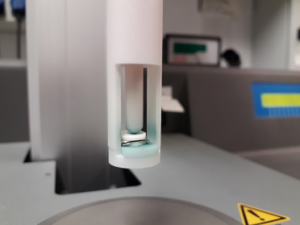

Dilatometer sample holder and test geometry

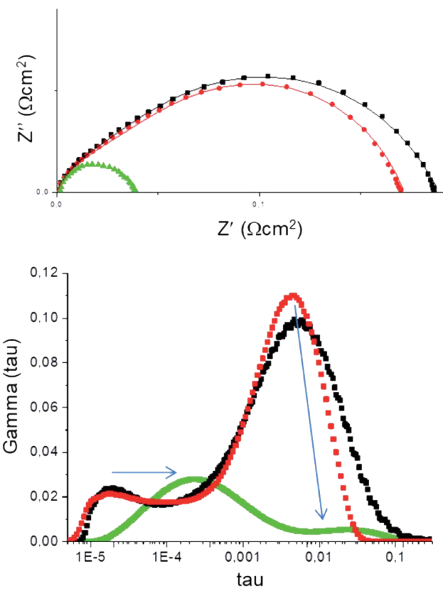

Electrochemical Characterization Equipment for Energy Materials and Devices

We have configured and updated the laboratories to carry out the electrochemical characterization of materials (ion or mixed conductors) and the testing of SOFCs, SOECs and Li-ion Batteries. For example we are equipped with Frequency Response Analyser (Solartron 1260), Potentionstats with EIS capabilities (VSP-PAR; Zhaner), Fuel Cell / Electrolysis test station (for up to 800 W power cells), EIS testing cell and sample holders of different kinds, gas flow controlers and humidity control, Gas Chromatograph, etc.

Cell and adjacent equipment for Fuel Cell and Electrolyser testing

Frequency Response Analyzer SOLARTRON 1260

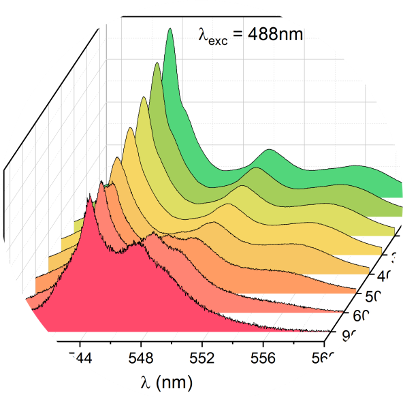

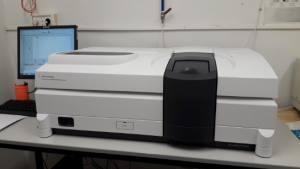

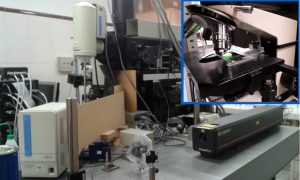

Optical Spectroscopy

We use optical spectroscopy in the research for structural and analytical studies in materials and electrochemical devices and to investigate specific optical properties of microstructured or high temperature materials. Therefore, our team brings together experts, users and researchers responsible for a Raman laboratory; VIS and NIR, in situ and portable spectrometers; and share responsibility for a CARY5000 optical absorption spectrophotometer.

UV-VIS-NIR optical spectrophotometer. CARY5000 form Agilent Technologies, equipped with accessories for diffuse reflectance (internal DRA and Praying Mantis), specular reflectance (fixed and variable angle).

Raman spectrometer. Model DILOR XY, equipped with liquid-nitrogen-cooled CCD detector, optical microscope for excitation and detection, lasers covering from 488 to 647 nm and setups for variable temperature measurements in controlled atmosphere from 4 K to 1500 K.

Selective thermal emission set up. Equipped with NIR 256-2.5 spectrophotometer or USB2000 VIS-NIR (both from Ocean Optics) and Pyrometer Impac, ISR12-LO MB33 (1000°C – 1500°C).

Mechanical Properties

3-point Flexure set-up. Electronic Universal Testing Machine (Instron 5565, UK).

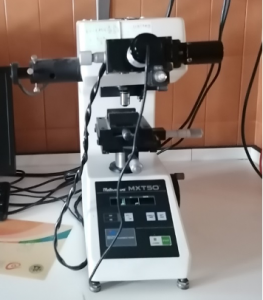

Nano and Micro indentation. Microhardness tester Matsuzawa, MXT 70.

Other INMA and UZ Facilities

We are frequent users of the following INMA and UZ Facillities:

- Electron Microscopy

- Surface Characterization and Confocal Microscopy

- XPS

- XRD and Fluorescence Analysis

- DSC, TGA